Promote learning through competition and strengthen safety through skills

The 9th Forklift Skills Competition

- Display skills, compare strengths, and promote communication -

In order to further strengthen the forklift driver's awareness of safe and standardized operations, improve the core skills of the job - especially the precise fork control and eye-hand-foot coordination, and at the same time stimulate the enthusiasm and competitive spirit of employees, at 13:30 pm on October 24, the finished product department took advantage of the production gap to organize and carry out the ninth forklift skills competition at the entrance of the forklift charging room. Forklift experts from various relevant departments gathered in the arena and launched a "stable, accurate and fast" strength competition.

Preparation before the game

Before the start of the competition, Hu Zhixin, the finished product manager of the organization department, made an opening speech, and Meng Xiaoming, the finished product team leader, explained the competition rules and safety points in detail through practical demonstrations, so that each player could clarify the process and understand the standard operating requirements.

▲ Product supervisor Hu Zhi’s opening introduction to the new work

▲ Meng Xiaoming, leader of the finished product team, explained the rules of the competition in practice

Arena competition

"Beep——" With a crisp whistle, the game officially started. The contestants, wearing overalls and safety helmets, had already completed the vehicle inspection according to the regulations. After getting on the vehicle and fastening their seat belts, they skillfully started the electric forklift and went straight to the "needle and thread" area.

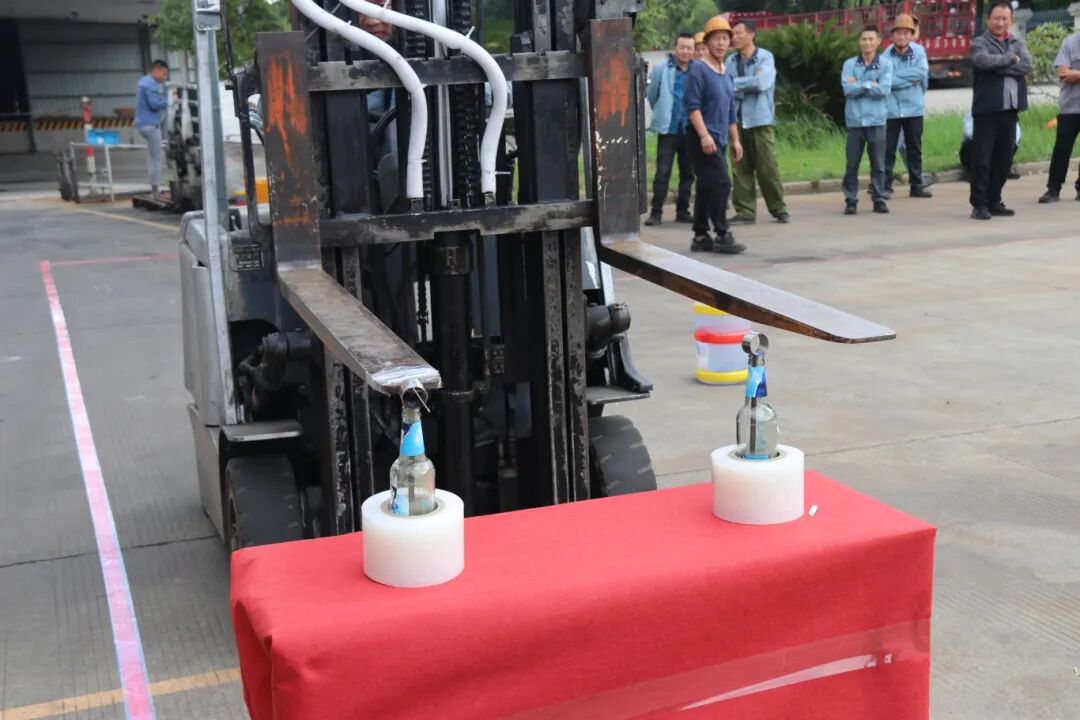

The core project of this time, "Threading the Needle", tests the "fine work" of forklift operation: a metal "needle" with a radius of only 2.5-5 mm is fixed on the front end of the fork, and the corresponding "thread" is a nut ring with an inner diameter of 1.5-3 cm. The competition proceeds in an orderly manner: the contestants must first let the "needle" pass through the nut accurately at the starting point, pass through the subsequent nut lifting, and then drive around the obstacle in an "S" curve, and finally reach the end point and put the nut upright into the wine bottle prop. The competition is limited to 8 minutes. The winner is determined by the total number of "needle threading-obstacle bypassing-standing placement" completed by the contestants. The winner is the one who completes the greater number.

|

|

|

|

On the field, the players were fully focused: some were paying close attention to the alignment angle of the fork and the nut ring, and fine-tuning the steering wheel; some were precisely controlling the lifting rod to allow the "needle" to pass through the ring smoothly; when penetrating the bottle mouth, they were holding their breath and concentrating, seeking stability while slowing down. From starting up, passing through rings, going around obstacles to putting the car in position, reversing back to the starting point and turning off the engine, every action demonstrates the daily accumulated operating skills, and bursts of praise can be heard from the sidelines from time to time.

|

|

|

|

|

|

Awards ceremony

After fierce competition, the winners of this competition are as follows:

First place: Finished product department – Wang Chenggang

Second place: Logistics information-Zhang Lili

Third place: Logistics information-Zhong Yueping

▲Second from the left, logistics information - Zhong Yueping, third from the left, finished product - Wang Chenggang, third from the right, logistics information - Zhang Lili

The ninth forklift skills competition not only set up a platform for forklift drivers to "display skills, compare strengths, and promote communication," but also strengthened all employees' awareness of "safety first, precise operation" in a competitive format. Through the competition, the players were further trained in core abilities such as eye-hand-foot coordination and fork fine-tuning. At the same time, they also learned the strengths of others and made up for their own shortcomings in the exchanges. The company will continue to use this type of skills competition as a starting point to internalize the "precision" and "stability" on the field into the behavioral standards of daily work, and effectively inject a solid skills foundation into improving production efficiency and ensuring safe production.

END

Graphic editing丨Human resources-Kanglu